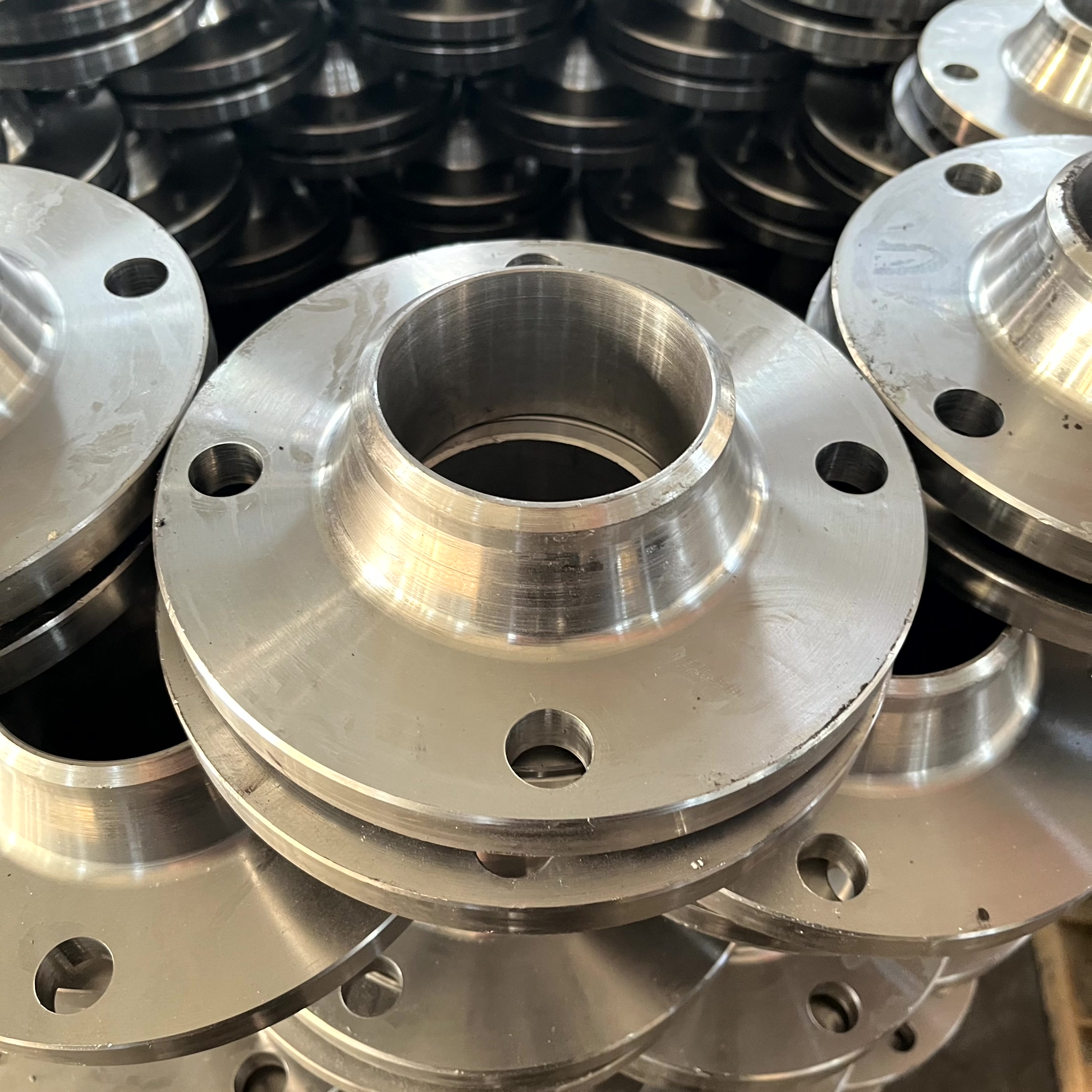

Product Overview: Optimized Stress Distribution for Critical Safety Connections

Our Tapered Hub Weld Neck Flange is a premium, forged component specifically engineered for the most severe and critical service conditions. Manufactured to comply with both ASME B16.5 (NPS 1/2 to 24) and ASME B16.47 (NPS 26 and above) standards, it offers an exceptionally wide pressure range, spanning from Class 150 up to Class 2500.

The core engineering advantage of this flange lies in its Tapered Hub design. This gradual transition minimizes stress concentration at the weld junction, ensuring smooth internal flow and providing unparalleled structural integrity and safety for high-pressure, high-temperature, or high-vibration piping systems.

🛠️ Technical Specifications & High-Pressure Performance

| Feature | Detailed Specification | Value Proposition |

| Design Highlight | Tapered Hub Construction. | Stress Dissipation: Smoothly disperses stress away from the pipe-to-flange weld, critical for the highest pressure ratings. |

| Standard Compliance | ASME B16.5 (Standard) & ASME B16.47 Series A & B (Large Diameter). | Comprehensive Coverage: Meets all industrial size and design code requirements, from small bore to 120}\text{″. |

| Material Options | Carbon Steel (A105, A350 LF2), Stainless Steel (F304/F316), Alloy Steel (F11/F22). | Service Customization: Flexible material choice to handle cryogenic, high-temperature, or aggressive corrosive media. |

| Pressure Rating | Class 150 up to Class 2500. | Ultra-High Pressure: Suitable for supercritical systems that require the utmost safety and load-bearing capacity. |

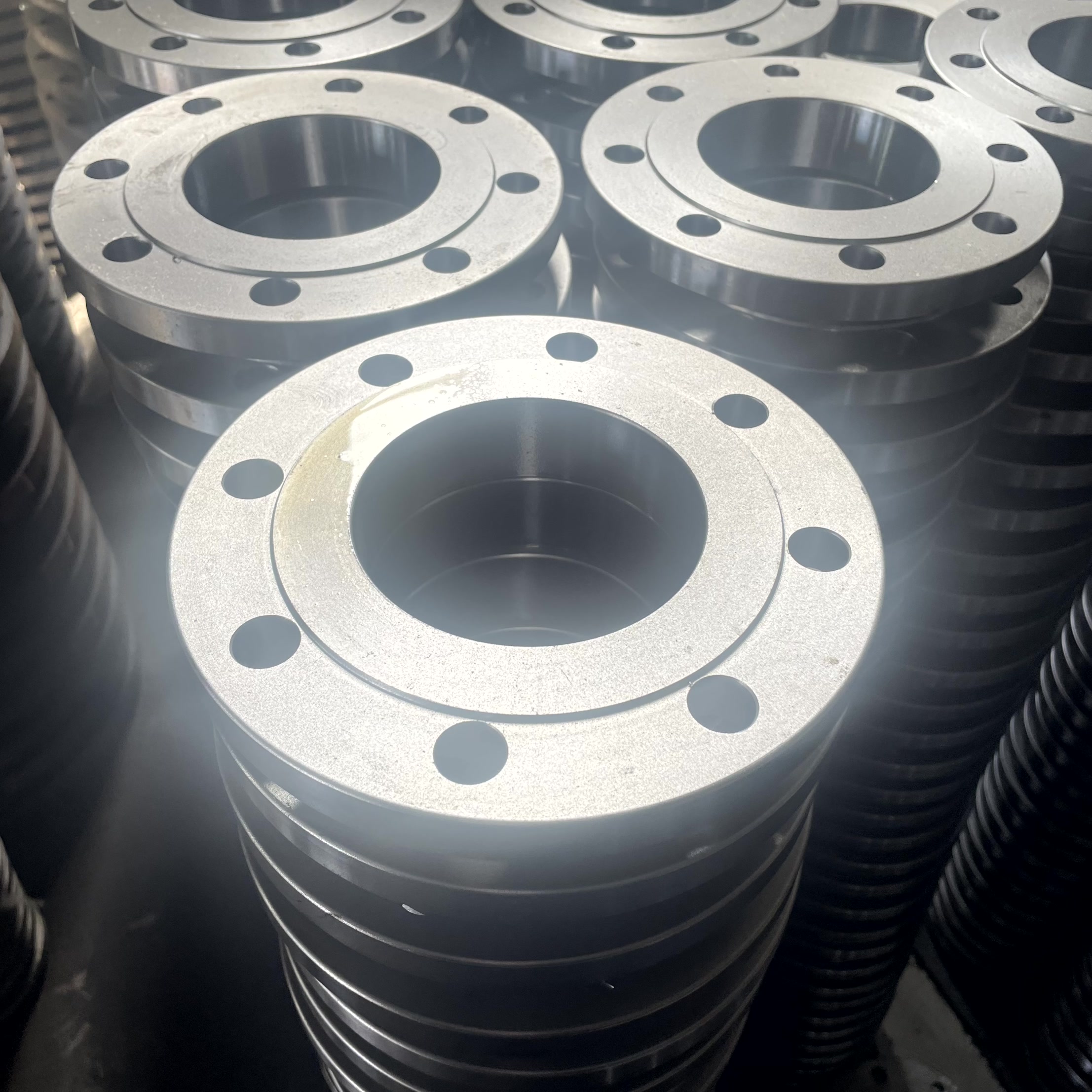

| Sealing Face | RTJ (Ring Type Joint), RF (Raised Face), FF (Flat Face). | Leak Prevention: The RTJ face provides superior protection against leakage in Class 300 and higher pressure connections. |

🌍 Key Service & Application Sectors

The Weld Neck Flange is the preferred choice for critical lines due to its reliability and suitability for NDT (Non-Destructive Testing). Our Tapered Hub design enhances its use in:

-

Oil & Gas (Upstream): High-pressure oil wells, gas compression, and transfer stations.

-

Power Generation: High-pressure steam and supercritical fluid transport systems.

-

Petrochemical & Chemical Processing: Critical connection points subject to pressure cycling and high thermal stress.

-

Large Infrastructure Projects: ASME B16.47 compliance supports heavy industrial applications up to 120}\text{″ diameter.

🏭 Partner with Hebei Cangtie — Assured Quality and Experience

Hebei Cangtie Industrial Co., Ltd is your specialized partner for high-pressure ASME flanges. Located in Cangzhou, China, we focus on the manufacturing and export of Weld Neck Flanges and custom forged components. With over 10 years of experience, our processes—from forging presses and CNC precision machining to comprehensive NDT verification—ensure every flange meets the highest standards dictated by ASME specifications.