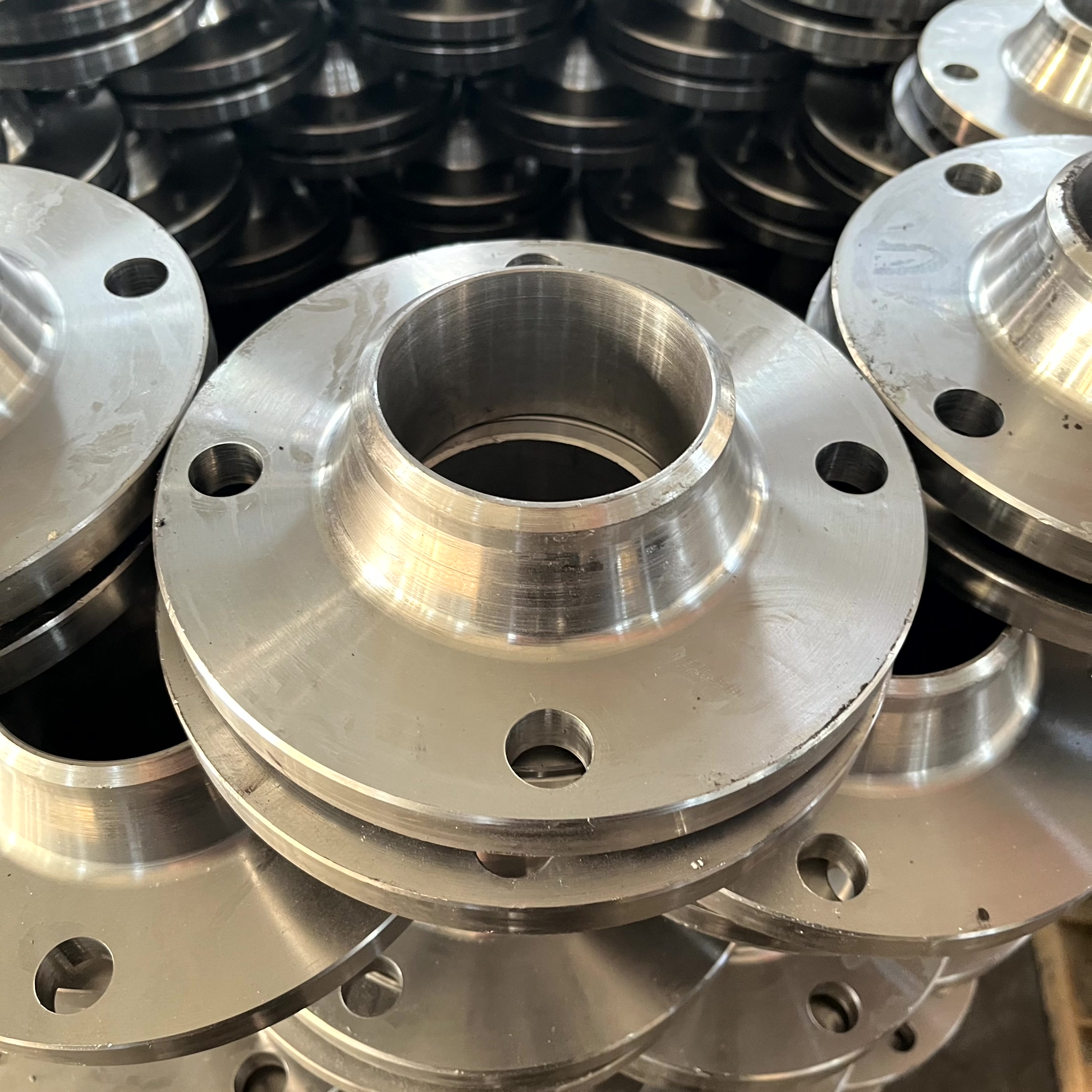

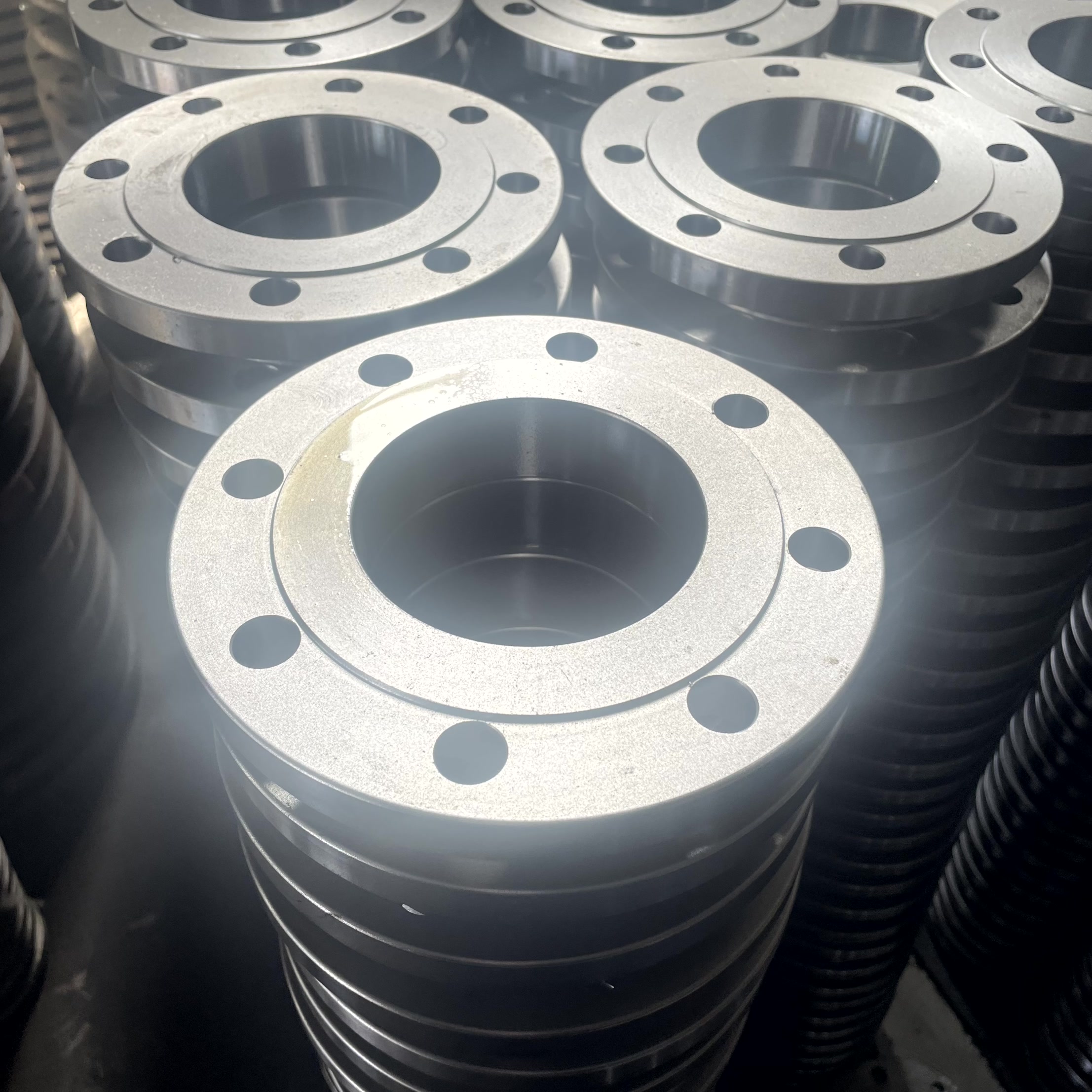

Heavy-Duty Threaded Pipe Flanges (ANSI B16.5 Standard)

Our Threaded Pipe Flanges are the ideal solution for creating secure, leak-proof pipe connections without the need for welding. As a leading industrial flange supplier, we provide high-quality forged carbon steel and stainless steel threaded flanges that strictly adhere to ANSI B16.5 and ASME standards. These are perfect for high-pressure systems and environments where welding is hazardous or impractical.

Technical Specifications & Size Chart

Below are the common specifications available in our inventory. We support both NPT (National Pipe Thread) and BSPT (British Standard Pipe Thread) to meet global project requirements.

| Size | Pressure Class | Thread Type | Materials Available |

|---|---|---|---|

| 1 inch (1") | Class 150# / 300# / 600# | NPT / BSPT / BSP | Carbon Steel A105, SS304, SS316L |

| 2 inch (2") | Class 150# / 300# / 600# | NPT / BSPT / BSP | Carbon Steel A105, SS304, SS316L |

| 3 inch (3") | Class 150# / 300# / 600# | NPT / BSPT / BSP | Carbon Steel A105, SS304, SS316L |

| 4 inch (4") | Class 150# / 300# / 600# | NPT / BSPT / BSP | Carbon Steel A105, SS304, SS316L |

Why Choose Our Threaded Flanges?

- Precision Threading: High-precision NPT/BSP machining ensures a tight, leak-proof fit with pipe ends, significantly reducing maintenance risks.

- Standard Compliance: Fully compliant with ASME/ANSI B16.5 forging standards. Mill Test Certificates (MTC) are provided for every batch.

- Global Logistics Support: Strategically stocked in USA (FL, TX, CA) and Australia (Sydney, QLD) hubs for rapid domestic and international delivery.

Threaded Flange FAQ

1. How do I measure a threaded pipe flange for replacement?

To accurately size a flange, you must confirm the Nominal Pipe Size (NPS), the Outer Diameter (OD), the Bolt Circle (BC) diameter, and the specific thread type (NPT or BSP). Refer to our downloadable dimension chart for exact measurements.

2. Should I use NPT or BSP threads for my project?

Generally, US projects predominantly use NPT (National Pipe Thread). However, Australian and European markets often utilize BSP/BSPT for gas and water systems. We stock both types to ensure local compatibility for our global clients.

3. What are the main benefits of using threaded flanges over welding neck flanges?

Threaded flanges allow for quick installation and easy disassembly for inspection. They are essential in hazardous areas where welding is not permitted due to fire or explosion risks.

Looking for Bulk Pricing or Technical Drawings?

Contact our expert team today for the full Threaded Flange PDF Specification Chart and the latest wholesale quotes. Global shipping is available with fast dispatch from our USA and AU centers.

Email: hudson@cangtiepipe.com

WhatsApp/Phone: +86 190 6177 3869